Hot-dip galvanizing

|

|

|

|

We offer hot-dip galvanizing services for construction metal products, pipe products, metal structures of any complexity, pipe fittings, etc.

Overall dimensions of the bath 13x2.3x3 meters

All stages of hot-dip galvanizing are carried out in accordance with GOST 9.307-89

The meaning of the galvanizing coat is the formation of a zinc layer with a thickness of 40 to 250 microns on the metal surface (the thickness of the coating is agreed with the Customer). It is understood that this layer will provide anti-corrosion protection of the metal surface from the effects of liquid and oxygen effects of the environment for years.

At the moment, hot-dip galvanizing is a reliable method of anti-corrosion protection of the metal surface, which will ensure the entire service life of the product.

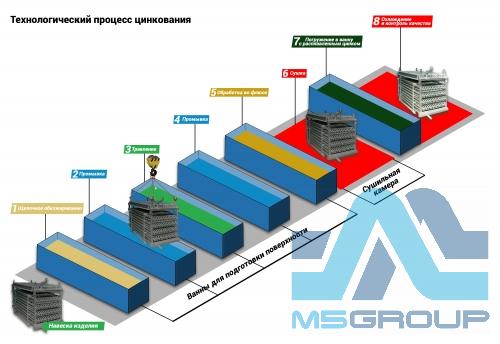

Stages of hot-dip galvanizing according to GOST 9.307-89:

Initially, the acceptance of the metal takes place in order to identify its features, structure, chemical composition, as well as surface contamination (a frequent occurrence is dried scale, it shall be cleaned before the galvanizing process, otherwise there will be a rejected material).

Then the metal is suspended on traverses for further processing.

Stage No. 1 - degreasing the metal surface

At this stage, the metal is completely cleaned of fat, it is dipped into a special solution based on hydrochloric and orthophosphoric acid containing surfactants.

Stage No. 2 - pickling the surface layer

This stage is necessary for thorough cleaning of the surface from contamination with oxides and salts.

Stage No. 3 - flushing with process water

This stage is necessary in order to avoid the negative impact of acids and salts

Stage No. 4 - fluxing

Final preparation of the metal for hot-dip galvanizing. The metal is immersed in a solution of zinc and ammonium chlorides, after which a film is formed, which provides protection against corrosion and a reliable connection with zinc.

Stage No. 5 - drying

Drying is needed to evaporate the remaining liquid before hot-dip galvanizing.

Stage No. 6 - hot-dip galvanizing

The zinc-coated metal is immersed in a bath with molten zinc (not less than 98%) with a temperature of 445 to 455°С, from 2 to 10 minutes

Stage No. 7 - cooling

The hot-dip galvanizing process is completed by extracting the metal from the zinc melt and cooling it in air or in a bath with water.

For the correct processing of your order, please, when sending an application, immediately indicate the following parameters:

- Product name (pipe, rolled metal, if it is a design, then a drawing is better);

- Overall dimensions and weight of one unit of metal products;

- Certificate for metal;

- The state of the surface of metal products shall be clean, rolled-up scale, pores, inclusions, welding slags, residues of molding paste, graphite, temporary anti-corrosion protection agents, marking, metal shavings, cutting fluid - with silicone oils, paper tags, burrs are not allowed;

- It is better to immediately inform the location of the technological holes for the traverses (the hole size shall be at least 10 mm);

You can send your application for the purchase of hot-dip galvanized products or only hot-dip galvanized products to the coordinates below.

We supply the entire range of pipe products (seamless hot-rolled and cold-rolled pipes, electric-welded pipes, large-diameter pipes, shell pipes, shaped pipes), as well as pipeline fittings (bends, tees, transitions, flanges, plugs) and construction metal products in Russia, the CIS, near and far abroad.

We supply the entire range of pipe products (seamless hot-rolled and cold-rolled pipes, electric-welded pipes, large-diameter pipes, shell pipes, shaped pipes), as well as pipeline fittings (bends, tees, transitions, flanges, plugs) and construction metal products in Russia, the CIS, near and far abroad.

Steel

Steelpipes

Piping

Pipingdetails

Pipes and parts

Pipes and partsin external and

internal isolation

Pipeline

Pipelinesupports

Pipes

Pipes according to foreign standards

Shell pipes and

Shell pipes andparts for circulating

water lines

Shut-off

Shut-offvalves

Construction

Constructionmetal rolling

Hot-dip

Hot-dipgalvanizing

Steel

Steelpipe piles

Profiled

Profiledflooring

Metal structures

Metal structures

- 454080, CHELYABINSK CITY

- LESOPARKOVAYA STREET, 8, OFFICE 207

- 8-800-55-11-078

+7 (351) 218-78-78 - E - mail: sales@group-m5.com